By Cox Marine

Demands for improved fuel economy, lower CO2 emissions, and enhanced performance is driving demand for diesel outboard engines. For those in the commercial maritime industry, public services or recreational boat owners, diesel outboards offer several advantages over petrol power, including high efficiency and torque that enables powerful thrust and acceleration. Switching to diesel fuel on outboards also supports single fuel source strategies for larger fleets using diesel elsewhere.

This guide covers everything you need to know about diesel outboard engines, including how they work, benefits, limitations, key trends, and engine types.

Content

- What is a diesel outboard engine?

- How diesel outboard boat engines work

- Back to basics – the different types of outboard engines

- Diesel outboard engines versus petrol outboards

- Electric outboard motors versus diesel

- How to choose the best diesel outboard engine for your boat in 2025

- The trends driving innovation

- The future of diesel outboard engines

- The Cox Marine V8: 300 & 350hp diesel outboards

- FAQ’s

What is a diesel outboard engine?

A diesel outboard engine is a self-contained, external propulsion motor, comprising an engine, gearbox, and propeller, mounted on the back (stern) of the boat. While petrol (gasoline) outboards are common in recreational boating, diesel outboards are typically used for more heavy-duty, long-range, and commercial applications. Their high efficiency, durability, and fuel safety make them an attractive option.

Diesel has higher energy density than petrol, which is the key to its superior fuel economy and a major advantage over longer distances, when fuel optimisation is a priority. Diesel engines also produce more torque, making them ideal for towing loads, moving heavy vessels, and working in harsh marine conditions. Furthermore, diesel is less flammable than petrol and therefore reduces the risk of fire in marine environments.

How diesel outboard boat engines work

One of the main advantages of a diesel outboard is improved fuel efficiency. This is due to the “lean-burn” technology that uses less fuel and more air to achieve the same level of performance as petrol engines, for example, but with 30 to 35% greater fuel economy. Lower fuel consumption also means fewer emissions that meet stringent environmental regulations.

The power mechanism of a diesel engine works on the principle of compression ignition. Air is drawn into the combustion chamber and compressed to high pressure. The fuel is then injected directly into the chamber, where the compressed air is so hot that the fuel ignites automatically creating an explosion that pushes the piston down, generating mechanical power. Any spent gases are subsequently expelled from the cylinder, and the process repeats.

Back to basics – The different types of outboard engines

Outboard engines for commercial use come in a variety of types based on fuel, power source, and intended application. These engines are widely used in industries such transportation, and maritime operations. Here is an overview of the main types of outboard engines and fuel options:

- Petrol:

There are two types of petrol engine –

Two-stroke engines: A simple engine design that combines fuel and oil. They are lightweight and have a high power-to-weight ratio. Although they are powerful, efficient, and cheaper than diesel, they have high fuel consumption and emissions – and therefore do not always meet environmental standards.

Four-stroke engines: These use separate oil and fuel systems, producing a more efficient and cleaner burn, but are heavier and generally more expensive than two-stroke engines. The largest petrol outboard motor is reported to be 600hp.

- Diesel:

Designed for heavy-duty use, offering more torque at lower revolutions per minute (RPMs). Diesel fuel is more efficient and cheaper than petrol, which is beneficial for long-term operation, and more durable and better suited for heavy loads.

The downside is higher upfront costs. Diesel engines can also be heavier, noisier, and more complex to maintain than petrol engines, but are ideal for long-distance travel and commercial activities that require reliable, heavy-duty performance.

- Electric:

Being powered by electricity, either through on-board batteries or hybrid systems, means that some electric outboards are completely emission-free, which is especially useful in areas with strict environmental regulations. Other benefits include quiet operation, minimal maintenance costs, and increasing range with advancements in battery technology. Most electric outboards still have a limited range and battery life so may be more suited to inflatable dinghies and lighter duty tenders. The most powerful electric outboard motor is reported to be 300hp with larger electric outboards on their way.

- Liquefied petroleum gas (LPG):

LPG (or propane) is an emerging alternative to petrol. This is because propane burns cleaner than either petrol or diesel, reducing emissions. They are more efficient and cheaper to operate. Propane also has a long shelf life, making it a reliable fuel for long-term storage. However, there is limited availability in certain regions and the range may be shorter compared to petrol or diesel engines.

- Hybrid:

These combine a traditional internal combustion engine (gasoline or diesel) with an electric motor, offering flexibility between power sources. This technology offers versatility with the ability to switch between electric and fuel power, allowing for emission-free operation when needed and the long-range capability of fuel engines when necessary. However, given the higher initial costs of hybrid systems, this technology is still developing for marine applications.

- Jet propulsion outboard:

These engines use a jet of water for propulsion instead of a propeller, powered by petrol or diesel. The absence of a propeller in this design makes them safer in shallow waters or around swimmers. They offer good manoeuvrability and can operate in very shallow water, although they are less efficient than traditional propeller-driven outboards and more prone to clogging with debris or seaweed. Therefore, maintenance costs are higher.

Diesel outboard engines versus petrol outboards

When comparing diesel outboard engines to petrol (gasoline) outboard engines, there are several factors to consider, including fuel efficiency, performance, longevity, safety, cost, and suitability for specific types of boating.

- Fuel Efficiency

Diesel fuel has a higher energy density than petrol, meaning diesel engines are typically more fuel-efficient. They use less fuel than petrol to travel the same distance, especially at low speeds and over long distances. This makes them ideal for long-range cruising or heavy-duty workboats.

Petrol engines tend to be less fuel-efficient compared to diesel, especially at lower speeds or when carrying heavy loads. However, they can be more efficient at higher speeds in certain conditions, especially in smaller, lighter boats.

- Performance

Diesel engines are known for providing high torque at lower RPMs, which makes them powerful and reliable for moving heavy boats or when towing loads. However, they often have a lower top-end speed and acceleration compared to petrol engines.

Petrol outboards tend to offer better acceleration and higher top-end speeds. They are more responsive and perform better in smaller, lighter boats that require more agility and speed.

- Durability and Longevity

Built for durability, diesel engines can often outlast petrol engines. They are designed to handle high stress and long operational hours, which is why they are commonly used in commercial and heavy-duty applications. Diesel engines can last significantly longer if properly maintained.

Petrol engines tend to have a shorter lifespan compared to diesel engines due to the higher operating temperatures and stresses. While they are still durable and reliable, they may require more frequent repairs and replacement over time, especially in heavy-use situations.

- Safety

Diesel fuel is less flammable than petrol, making diesel engines safer in terms of fire risk. This is particularly important for certain applications such as commercial boats, military vessels, or offshore platforms where safety is a top priority.

In contrast, petrol is more volatile and flammable, posing a higher fire risk. This can be a concern in enclosed spaces like engine compartments on boats, though modern safety features and proper handling significantly mitigate these risks.

Mass storage of petrol can also be a problem for large operators with hazardous area and ATEX compliance (Europe) considerations.

- Single fuel source strategies

For many operators, having one single fuel source across a fleet where inboard diesel engines are also used, helps to reduce costs, limits storage problems, reduces suppliers and saves space.

- Cost

Diesel outboards are typically more expensive upfront compared to petrol outboards due to their more robust construction and complex design. However, this higher cost is often offset by long-term fuel savings and longer engine life, whereas petrol outboards are usually cheaper to purchase initially but can have high running costs due to their higher fuel consumption rate.

- Environmental Impact

Diesel engines typically produce more particulate matter (PM) and NOx emissions, which can be harmful to the environment. However, advancements in diesel engine technology have helped reduce emissions. Additionally, since diesel engines are more fuel-efficient, they burn less fuel overall, which can reduce their carbon footprint.

Modern petrol engines, particularly those with four-stroke technology, are relatively clean in terms of emissions and often meet strict environmental standards. However, two-stroke petrol engines, which are still used in some outboard applications, can be less environmentally friendly due to higher emissions.

- Maintenance

Diesel engines typically require less frequent maintenance and fewer repairs due to their simple and robust design. However, when they do need repairs, the parts and labour costs can be higher due to the specialized nature of diesel engines.

Petrol engines, particularly smaller ones, tend to be easier and cheaper to maintain, with parts that are widely available and less expensive. However, they may require more frequent maintenance, especially in harsh marine environments.

Electric outboard motors versus diesel

Electric and diesel outboard motors are two distinct propulsion technologies used in marine applications. Each has its advantages and drawbacks depending on the use, cost, environmental impact, and performance requirements:

- Power and performance

Diesel outboards generally provide higher power and torque, making them suitable for larger vessels, heavy-duty tasks, and long trips. Diesel engines are known for their durability and ability to manage high loads over extended periods, making them ideal for commercial and industrial use, however they are noisy and produce vibrations that might be uncomfortable for some users.

Conversely electric outboards are quieter and have instant torque, meaning they provide immediate propulsion as soon as the throttle is engaged. They are typically better suited for smaller boats and shorter-range applications, though larger models for larger vessels are emerging. Electric motors generally do not match the long-range power of diesel motors, but this is improving with battery advancements.

- Fuel and energy efficiency

While diesel engines are more fuel-efficient than petrol engines, they still consume fossil fuels, contributing to ongoing fuel costs. However, they can cover longer distances on a single tank of fuel, making them ideal for offshore or long-haul trips.

Electric outboards are powered by batteries and are usually much more energy-efficient than combustion engines. Depending on battery size and usage, they can offer a good range, but extended trips require planning to ensure battery capacity. With infrastructure investment, recharging can take place at marinas with charging stations or through renewable energy sources (e.g., solar panels). With no fuel costs involved, except for charging, electric outboard engines are more cost-effective in the long term.

- Maintenance

Diesel engines require regular maintenance, including oil changes, filter replacements, and fuel system upkeep. They are also more complex, which can result in higher repair costs over time, especially for older engines.

On the other hand, electric motors are much simpler in design, with fewer moving parts, meaning significantly lower maintenance. This means they do not require oil changes or fuel system upkeep, and their components are often more reliable in marine environments. However, the battery systems need careful management, and battery replacement costs can be high after a few years.

- Environmental impact

Diesel engines emit greenhouse gases (CO2) and other pollutants, including nitrogen oxides and particulate matter, and fuel spills can be harmful to marine ecosystems. In contrast, electric outboards produce zero emissions at the point of use, making them environmentally friendly and compliant with stricter marine emissions regulations.

If recharged with renewable energy, electric motors can have a minimal carbon footprint. Battery production and disposal can still have an environmental impact, but this is typically lower than the emissions from fossil fuels.

How to choose the best diesel outboard engine for your boat in 2025

To make an informed decision, consider the specifications of different engines to ensure the model you choose fits your requirements. It is also worth looking into practical information on preventing problems, troubleshooting, and making repairs:

- Horsepower and torque: Determine the size of the engine based on your boat’s weight, type of usage and the loads you plan to carry. Commercial boats often benefit from higher horsepower and torque to handle heavier payloads.

- Fuel consumption and range: Diesel engines excel in fuel efficiency, but you should still calculate your boat’s range requirements and ensure that the engine can deliver the performance needed over long distances.

- Maintenance needs: Although you can benefit from longer service intervals, diesel engines may require more specialised maintenance. Choose a brand with a good service network and availability of spare parts in your area.

- Environmental and regulatory compliance: Ensure the engine meets emissions regulations in your region. New diesel outboards are engineered to comply with stringent emissions standards set by organisations like the Environmental Protection Agency (EPA) and the International Maritime Organisation (IMO).

- Weight and boat compatibility: Diesel outboards tend to be heavier, so it is essential to ensure your boat can manage the extra weight. Verify your boat’s maximum transom weight rating and how the added weight will affect balance and performance.

The trends driving innovation

As environmental regulations tighten, manufacturers will continue to prioritise nitrogen oxide (NOx) and particulate emission reductions in new models to comply with IMO Tier III and EPA standards. Revised guidelines from the IMO suggest alternative power and propulsion systems could help reduce underwater radiated noise (URN), while electric propulsion (e.g. diesel-electric, fuel cell and full electric or battery, podded propulsions or azimuth thrusters) is considered a promising configuration option for reducing underwater noise. The use of high-quality electric motors and installations could also help to reduce vibration induced in the hull from the electric motor.

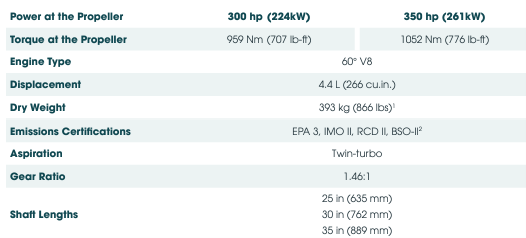

For this reason, manufacturers are focused on developing diesel outboard designs that enhance fuel efficiency and reduce emissions. As such, new product development is focused on clean-burning, sustainable engines that meet both existing and evolving environmental standards and deliver economy savings. For example, the Cox purpose-built V8 twin turbo high-performance diesel engine emits low emissions and noise levels, but with peak torque and at least 30% improved fuel efficiency, ideal for commercial operations and leisure use.

Hybrid diesel-electric outboards are also emerging as an eco-friendly option. In coastal and environmentally sensitive areas, such as national parks and protected marine areas, where silent, low-emissions operation is a significant advantage for hybrid outboards.

The future of diesel outboard engines

Diesel outboard motors are an excellent choice for maritime businesses and public service bodies that need to prioritise fuel efficiency, safety, and boat durability. While they come with a higher upfront cost, the benefits in terms of torque, fuel savings, and longevity often justify the investment, particularly for commercial operators wanting a single fuel source.

Whether you are looking to upgrade your boat’s engine or considering a new build, diesel outboards can provide reliable power for a wide range of marine activities. With advancements in technology, the maritime industry can expect even more efficient, environmentally friendly diesel outboards in the future.

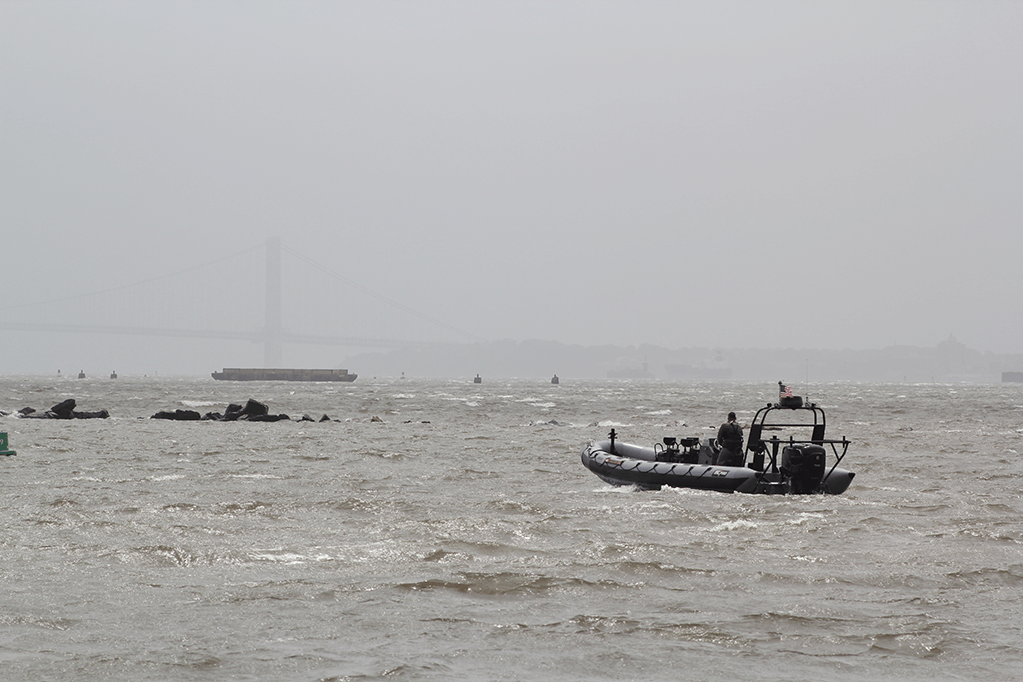

The Cox Marine V8: 300 & 350hp diesel outboards

Cox diesel outboards are the most effective alternative to petrol outboards offering several key benefits. Significantly lower costs with a 30% improvement in fuel efficiency compared to petrol (gasoline) outboards, supporting single fuel source strategies for fleets already using diesel, and enhancing onboard safety. Cox engines meet stringent environmental standards and are built to withstand the harshest marine conditions, ensuring reliable performance and longevity in real-world applications, from sportfishing to commercial boating across the world.

LINK TO SPEC SHEET

FAQ’s

What is the most powerful diesel outboard?

The world’s most powerful Diesel Outboard engine, Cox Marine 350hp as cited by Dpower.

What is the most environmentally friendly high-powered outboard?

The Cox Marine V8 is the only high-powered diesel outboard awarded BSO-II, not just with a single install but a twin. In addition to its EPA Tier 3, RCD II, RCR II and IMO II emissions certifications.

Are all diesel outboards made using automotive engines?

No, the Cox Marine V8 is the only high-powered diesel outboard created from a blank-sheet design specifically for the marine application. As opposed to other options that used marinised automotive powerheads.

With diesel outboards being so new to the market, are they difficult to get serviced/support?

Cox Marine is currently represented in more than 175 territories across six continents by expertly trained technicians – a number that will continue to grow.